Show Case

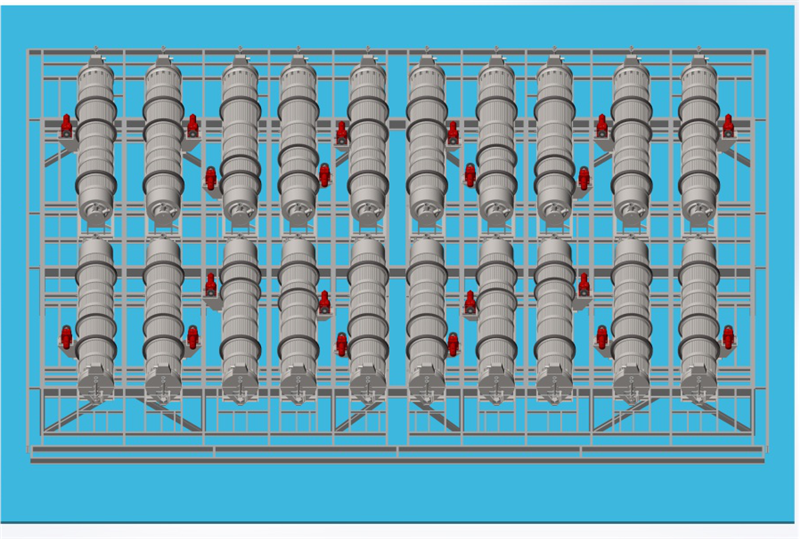

Case(1) Rotary Ash Coolers for 2x235MW Attarat Oil Shale Power Plant, Jordan (SHI FW Boiler)

Project Details

Owner: Attarat Power Company

Owner Engineer: Mott Macdonald, UK

EPC Contractor: Guangdong Power Engineering Co., Ltd.

Technical Advisor of EPC Contractor: Worley Parsons, China

Features

– 2 x 235MW boiler supplied by SHI FW

– 40 x 30t/h ash coolers for bottom ash by Songling

– 8 x 6t/h ash coolers for horizontal pass by Songling

– Boiler Bottom Ash flow (worst case): 501TPH/per Boiler

– Cooling water: condensate water

– Design pressure: 3.9Mpa

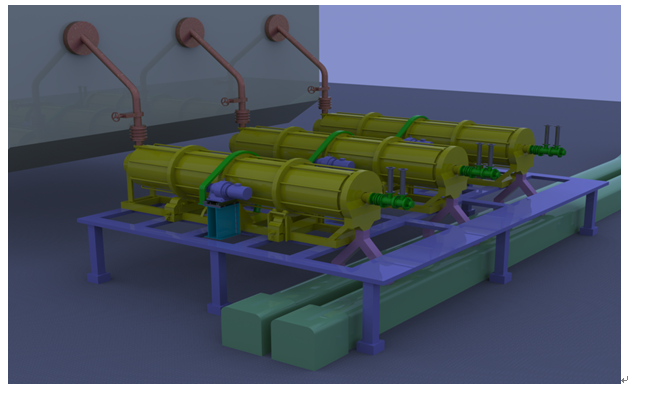

Case(2) Rotary Ash Coolers for NARVA 2*300MW CFB Power Plant Project, Estonia

Location

In the district of Vaivara, the north east of Estonia near the border with Leningrad Oblast, Russia and the Baltic sea.

Features

Project: Narva 2×300MW CFB Power Plant Project

Estonia Owner: Narva Elektrijaamad AS, Estonia

EPC Contractor: Alstom (France)

Purchaser: Alstom Estonia AS

Fuel: Oil Shale

PO Efective Date: March, 2012

Scope of Supply: 6×21ton/hr Rotary Ash Coolers for each Unit

Delivery Date: February, 2013

Design and Fabrication Code:

-ASME Vll, and in compliance with the following EC directives:

-Machine Directive 2006/42/EC

-Pressure Equipment Directive 97/23/EC

-Low Voltage Directive 2006/95/EC

-Electromagnetic Compatibility Directive 2004/108/EC

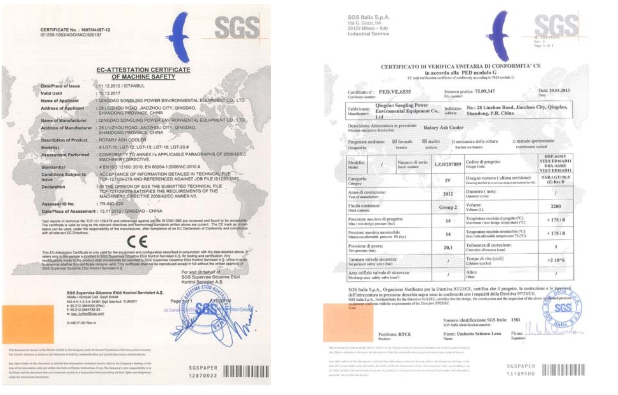

CE Certificates:

Case(3) Ash Handling System for STANARI 1*300MW CFB Project, Bosnia and Herzegovina

Location

Near the Stanari lignite mine, Bosnia and Herzegovina

Features

Project: STANARI 1×300MW CFB Power Plant, Bosnia and Herzegovina

EPC Contractor: Dongfang Electric

Fuel: Lignite

PO Effective Date: March, 2012

Scope of Supply: Rotary Ash Coolers, Bucket Conveyor, Bucket Elevator, Bottom Ash Silo, Fly Ash Silo, Bottom Powder Silo, Bed Material Silo

Delivery Date: April, 2014

Design and Fabrication Code:

-ASME, and in compliance with the following EC directives:

-Machine Directive 2006/42/EC

-Pressure Equipment Directive 97/23/EC

-Low Voltage Directive 2006/95/EC

-Electromagnetic Compatibility Directive 2004/108/EC

Case(4) Ash Handling System for 10×135MW Jindal Steel & Power (SBW boiler), India

Location

Harghoda, District Raigarh, India

Features

· 10×135MW boilers supplied by SBW

· 4×25t/h Rotary ash coolers for each boiler in 01/2009

· Ash system including ash cooler, bucket conveyor and ash silo

· Cooling water: DM water

· Design pressure: 1.2Mpa

· Ash outiet temperature: <150℃

Case(5) Ash Handling System for Adani Power Station Phase lll 5*660MW, India

Location

Aatmajyoti housing society, Navkar Apartment, Plot No.11,S.R. NO,206/3

Mundra, Baroi Road, Mundra-Kutch-370421 Guiarat, India

Features

· 5×660MW Boliers, Supplied by HBW

· 1SFC for per boiler

· Delivered in 06/2008

· Auxiliary equipment including ash hopper, Cut off gate, ash silo

· Hydraulic motor drive, SFC attach to silo directly

Case(6) POSCO Chemical Synthetic Graphite and Lithium Battery Anode Material Plant Project, South Korea

Location

Pohang-si, Gyeongsangbuk-do, Republic of Korea

Features

· Project Owner: POSCO Chemical

· 2 x 20t/h ash coolers supplied by Songling

· Material inlet temp.: 350-600℃

· Material outlet temp.: ≤80℃

· Cooling water: Sofened water

· Inlet water pressure: 0.3Mpa

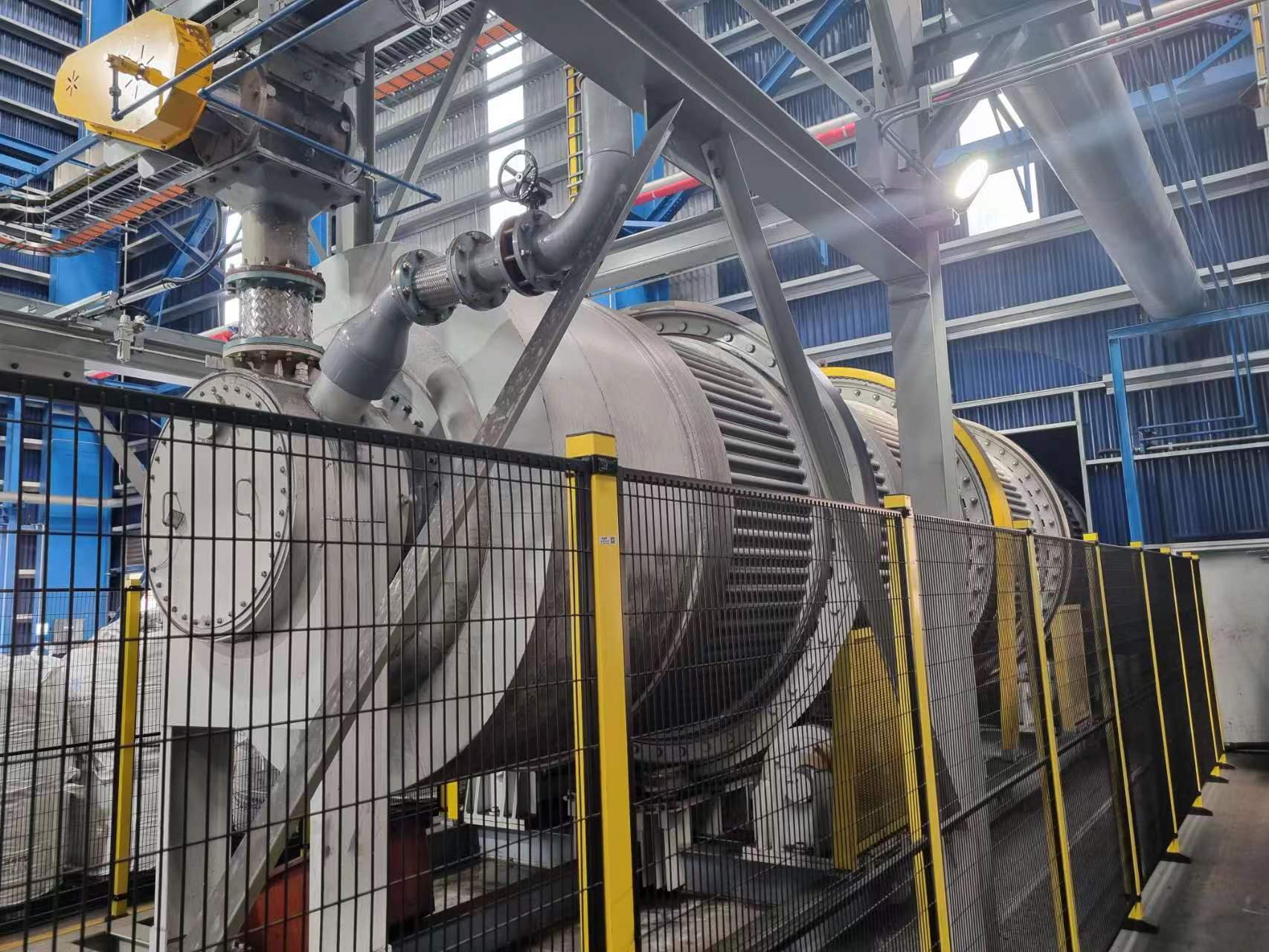

Case(7) Shenhua Shendong Guojiawan Power Plant 2x300MW, China

Location

Fugu county, Shanxi, China

Features

· 2×300MW CFB boilers supplied by HBW

· Complete line of ash handling system from cooler to silo supplied by Songling

· Descriptions: ash from boiler sidewall, 6 coolers for per boiler, 3 ash conveying line and 1silo for per boiler,

each line including 1 chain bucket conveyor and 1 bucket elevator

Case(8) Suancigou Power Plant 2x300MW, China

Location

Zhunger county, Neimongol, China

Features

· 2×300MW Unit, 2×1025t/h CFB boilers supplied by DBW

· Complete line of ash handling system from cooler to silo unloading system supplied by Songling

· Descriptions: ash from boiler front wall, 6 coolers for per boiler, 1 ash conveying line working and 1 ash conveying line standby, and

1 silo for per boiler, each line including 1 chain bucket conveyor and 1 bucket elevator. Silo furnished with 2 wet ash unloading systems.

E-mail: inquiry@qdsongling.com info@qdsongling.com

Web: www.qdsongling.com SEO

© 2022 SONGLING All rights reserved